SOLUTIONS

Enabling RTLS & RFID Asset Visibility

for the Automotive Industry

Unlock the full potential of your automotive operations with advanced RFID and IoT solutions. From supply chain visibility to real-time asset tracking, Acceliot is your partner for streamlined, smarter production.

KEY BENEFITS

Smart RFID Automotive Applications

- Vehicle Tracking

- Parts tracking

- Tool tracking

- Lot management

- Traceability

- Non-conforming material

Unlock Real-Time Efficiency Today

Ready to enhance your automotive production? Contact us to discover how Acceliot’s technology can streamline your operations and boost efficiency.

Introducing Acceliot AVP-Automotive:

Asset Visibility for Automotive OEMs

Designed to support vehicle tracking, lot visibility and parts management objectives

Acceliot’s AVP-Automotive suite offers a range of benefits:

- Delivering filtered asset data to visualization apps

- Streamlining testing, inspection and repair processes

- Reducing manual tasks

- Detecting manufacturing anomalies

- Enhancing end-of-line (EOL) manufacturing programs

- Improving first-time through (FTT) initiatives

- Optimizing vehicle tracking and marshaling

- Automating lot management processes

- Incorporating contextual data into production planning and control systems (PPCS)

- Automating supplier cage registrations

- Optimizing returnable transport item (RTI) management

ACCELIOT DELIVERS

Indoor, Outdoor and In-Transit

Acceliot’s integrated IoT/RFID platform enables real-time, accurate data of all assets in loading dock, manufacturing, logistics and shipping environments. By aligning the physical data with ERP/WMS systems, teams can add value to their automation strategies, embrace Industry 4.0 objectives and enable (more) intelligent business decisions.

Building ROI through enhanced workforce automation and via the intelligent tracking of components, assemblies, tools and finished vehicles is achieveable and within reach with an Acceliot-powered solution.

REAL WORLD ACHIEVEMENT

Automotive RTLS

- A major US automotive manufacturer tracks 30,000 vehicles in open yards using the STARflex system to reduce the time to locate vehicles from days to minutes. By reducing the intensive labor effort, the need for a contingent workforce was eliminated. Our customer also optimized the utilization of its repair and final inspection workstation.

- A European automotive manufacturer wanted to minimize manual processes, enable faster registration, optimize tracking and tracing of assets and reduce errors. Significant results were achieved through our RTLS coverage of their 200,000-square-foot facility and the full integration of smart gate technology.

WHY CHOOSE US?

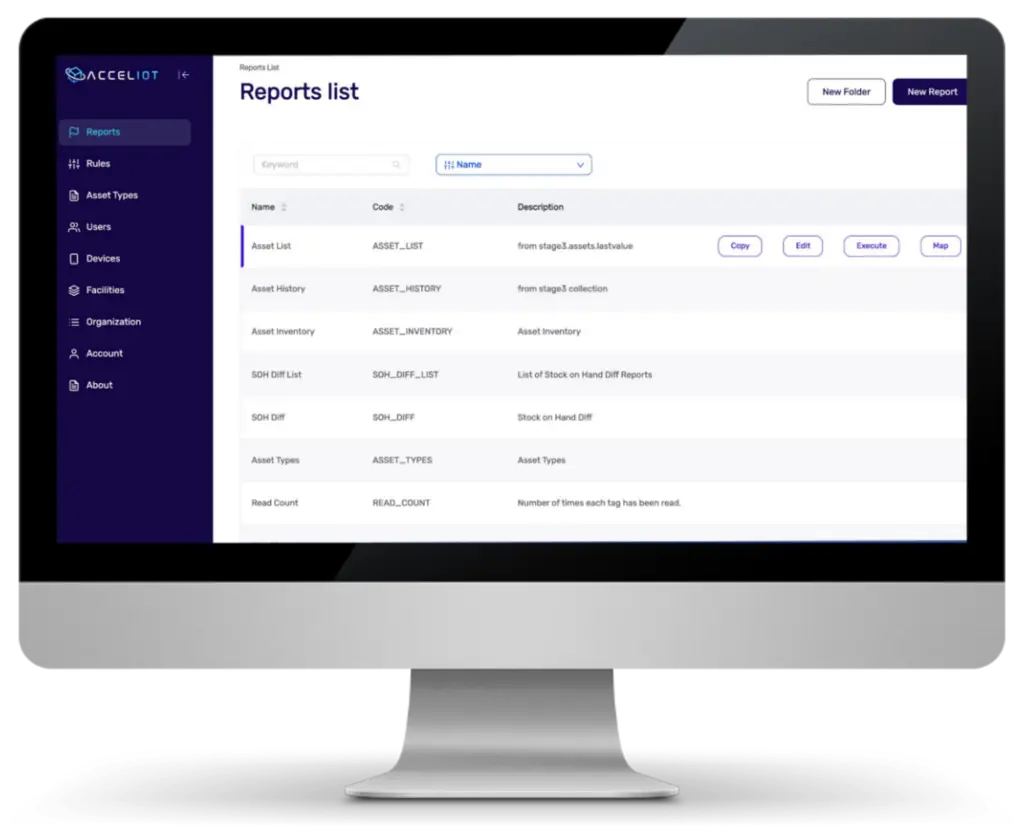

Acceliot RFID Powers Advanced Data Services

New RFID data-driven models for real-time asset visibility programs

Tailored RFID solutions supporting real-time traceability across the entire supply chain

Hardware and software solutions purpose-built for the era of AI-informed data

Take Control of Your Supply Chain

Are you ready to improve your automotive manufacturing with real-time data and tracking solutions? Talk to us today about integrating Acceliot’s cutting-edge technology into your operations.

WHY CHOOSE US

Acceliot's Proven RFID Technology Stack

High-Performance RFID

Our STARflex RFID readers deliver unprecedented tag read characteristics and set the standard for passive RFID asset tracking.

RTLS Software

Our team delivers market-leading application development and support services built upon a 20-year history of excellence in the field.

Advanced Signal Processing

We deliver RTLS solutions with passive RFID economics; leveraging our leading-edge disruptive phased array antenna design.