SOLUTIONS

Advanced RTLS & RFID Solutions

for Manufacturing Efficiency

Transforming operations by optimizing processes and enhancing efficiency

DEEP DOMAIN EXPERTISE

How RTLS Improves Asset Tracking in Manufacturing

With 20 years of innovation at the core, Acceliot’s STARflex technology platform simplifies the management of complex supply chains and also ensures that every component is interconnected and communicating effectively — enabling a seamless flow of information and goods.

- Inventory management

- Work-in-process (WIP)

- Shipping and receiving

- Asset tracking

- Personnel and visitor safety

- Factory floor security

WHY IT'S IMPORTANT

The Benefits of RFID for Manufacturing Inventory Management

Acceliot’s RTLS and RFID technologies provide manufacturers with real-time visibility and control over their assets, including machinery, tools, and inventory. By implementing RFID in manufacturing, companies can achieve greater precision in work-in-process tracking, improve production flow, and ensure that all assets are optimally utilized. RTLS in manufacturing enhances operational efficiency by allowing businesses to monitor the location and status of every component at all times, streamlining production, reducing costs, and increasing productivity. Acceliot’s solutions are designed to integrate seamlessly into existing workflows, enabling manufacturers to stay ahead in the Industry 4.0 revolution.

ACCELIOT DELIVERS

Real-Time Location Systems (RTLS) for Manufacturing Operations

Asset tracking: Acceliot RFID can dramatically improve the visibility, control and management of your assets, including returnable transport items (RTIs), tools, machinery, and IT assets, enabling you to maximize their utilization and minimize asset pool investment.

Inventory management: Accurate inventory is the key to omnichannel and e-commerce today. Not being able to count on the system inventory is costing companies in the form of lost sales. Our smart inventory solution uses RFID and advanced sensor technology to ensure high inventory accuracy with minimal human interaction.

TAILORED RFID SOLUTIONS

Industry 4.0

The synergy of IoT and RFID technology is emerging as a distinguishing factor in advanced logistics and supply chain management. An Acceliot-powered RFID solution can facilitate error-free, real-time efficiency and visibility across all operational sectors. Our cutting-edge digital solutions offer full automation capabilities, encompassing production, warehousing, distribution, and retail activities.

Our RFID-powered solutions enable smart manufacturing through the integration of IoT sensing with AI-powered decision engines customized for your environment. Acceliot can help catalyze your automated manufacturing strategies and deliver tracking, traceability and visibility of all stationary and moving items.

WHY CHOOSE US?

Acceliot RFID Powers Advanced Data Services

Value-added solutions including temperature measurement, moisture detection and more

Tailored RFID solutions supporting real-time traceability across the entire supply chain

Hardware and software solutions purpose-built for the AI-informed era of data management

Streamline Manufacturing Operations with Acceliot’s RFID Technology

Send us your most complex asset tracking challenges.

WHY CHOOSE US

Acceliot's Proven RFID Technology Stack

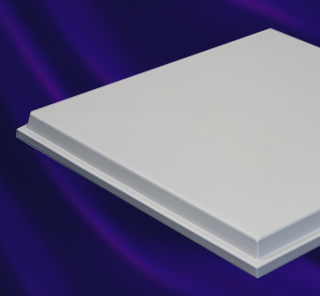

High-Performance RFID

Our STARflex RFID readers deliver unprecedented tag read characteristics and set the standard for passive RFID asset tracking.

RTLS Software

Our team delivers marketing-leading application development and support services built upon a 20-year history of excellence in the field.

Advanced Signal Processing

We deliver RTLS solutions with passive RFID economics; leveraging our leading-edge disruptive phased array antenna design.