Introduction

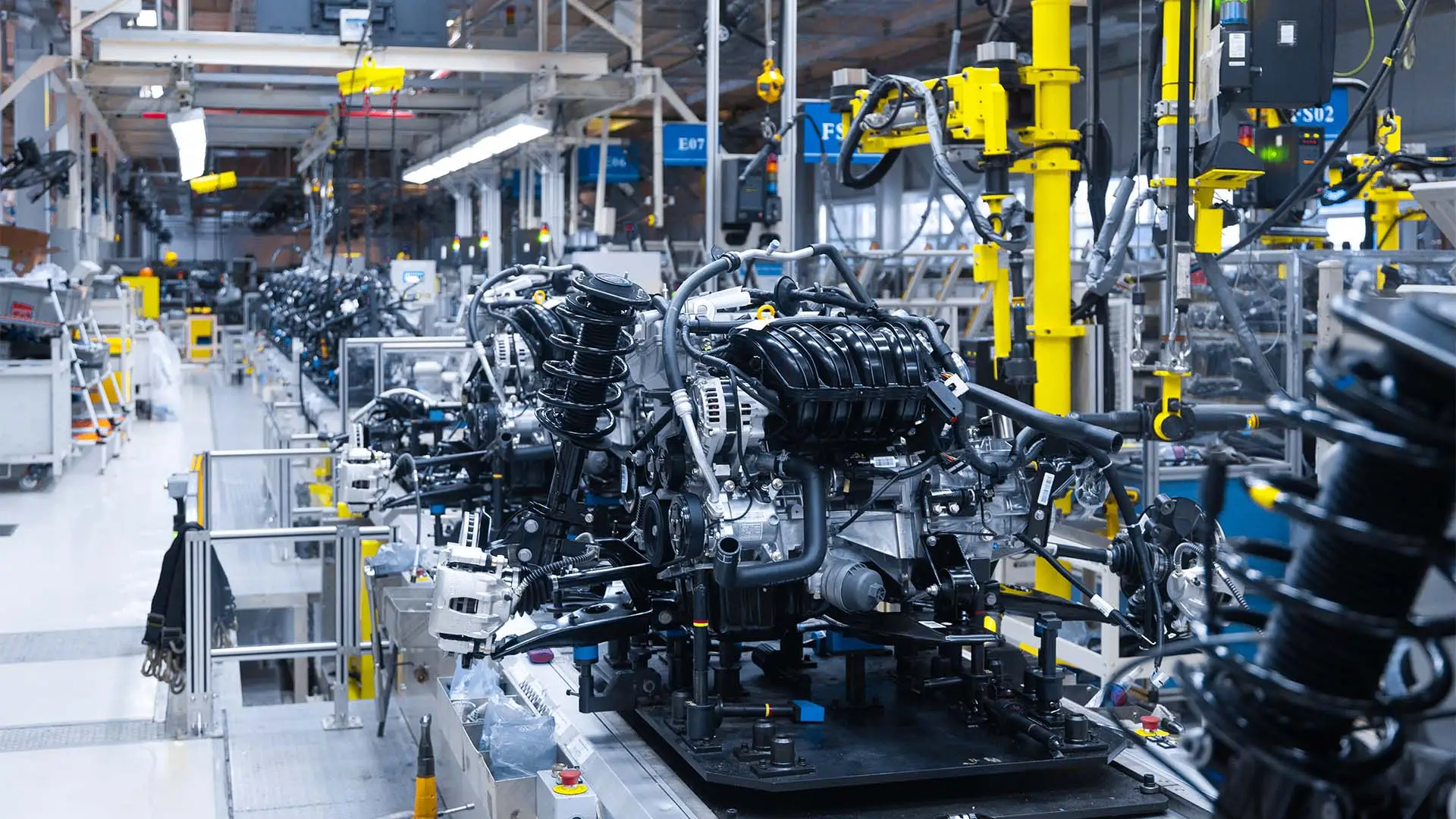

The automotive manufacturing industry has always been at the forefront of adopting new technologies to improve efficiency and quality. One of the key innovations making a big impact is RTLS, or Real-Time Location Systems. These systems help manufacturers keep track of vehicles, parts, and equipment, leading to smoother operations and fewer delays. In this blog, we’ll take a closer look at how RTLS is transforming automotive manufacturing in simple terms, focusing on the most important benefits and applications.

A Real-Time Location System (RTLS) is a technology that helps track the location of things like vehicles, tools, and parts in real time. Think of it as a way for manufacturers to always know where their important items are, just like how GPS helps you know where your car is. RTLS uses small tags attached to items and sensors placed around the factory to track where everything is at any moment.

For car manufacturers, this real-time tracking is incredibly valuable. It means they can keep production lines running smoothly, make sure all the necessary parts are in place, and reduce the time spent searching for lost or misplaced items.

Key Benefits of RTLS in Automotive Manufacturing

RTLS is making a significant impact in the automotive industry by offering several key benefits:

1. Improved Efficiency

One of the biggest advantages of RTLS is that it helps make everything more efficient. By knowing where every part, tool, and vehicle is in real time, manufacturers can avoid delays and keep the production line moving. If a tool or part is missing, workers can quickly find it instead of wasting time searching.

2. Reduced Production Delays

Delays in manufacturing can be costly. RTLS helps prevent these delays by ensuring that all parts are available when needed. When every component is tracked, it’s easier to spot potential issues before they cause a slowdown.

3. Better Inventory Management

RTLS makes managing inventory much easier. Instead of manually checking stock levels, the system provides real-time data about where parts are and how many are available. This means manufacturers can avoid running out of critical parts and keep production on track.

4. Enhanced Safety

Safety is always a priority in manufacturing. RTLS can help monitor the movement of equipment and people to ensure everyone is in the right place and that safety protocols are being followed. This reduces the chances of accidents on the factory floor.

A car manufacturer uses RTLS to track vehicles as they move through the assembly line. Each vehicle has a tag that sends out signals, which are picked up by sensors around the factory. The system shows exactly where each vehicle is and what stage of production it’s in. This means that if there’s an issue—like a delay in getting a part—the team can quickly see it and fix the problem before it affects the entire production schedule.

Another example is tracking tools. In a large factory, tools can easily be misplaced, causing unnecessary delays. With RTLS, each tool is tagged, and its location is always visible. Workers can quickly find the tools they need, which keeps everything running smoothly.

Summary

RTLS is changing the way automotive manufacturers operate by providing real-time visibility into their production processes. It helps improve efficiency, reduce delays, manage inventory better, and enhance safety on the factory floor. By knowing exactly where vehicles, tools, and parts are at all times, manufacturers can keep their operations running smoothly and deliver high-quality products on time.

Acceliot is proud to be at the forefront of this transformation, offering advanced RTLS solutions that help automotive companies optimize their production processes. If you want to learn more about how RTLS can benefit your business, reach out to us today.

Ready to transform your automotive operations? Contact Acceliot for a demo and see how our solutions can make a difference.

By integrating RTLS into your automotive operations, you’re not just adopting new technology—you’re unlocking new levels of efficiency, quality, and competitiveness. Let Acceliot guide you toward a smarter, more connected future.

RTLS is used in various ways to improve automotive manufacturing. Here are a few examples:

RTLS is also used for managing vehicle lots by Original Equipment Manufacturers (OEMs). After vehicles are assembled, they are often moved to large lots where they wait for quality checks, shipping, or distribution. With RTLS, OEMs can efficiently manage these lots by knowing exactly where each vehicle is located. This real-time visibility reduces the time spent searching for specific vehicles, streamlines the inspection process, and ensures that vehicles are ready for distribution without unnecessary delays.

Tracking Vehicles on the Assembly Line

As vehicles move through the assembly line, RTLS helps keep track of their progress. This visibility allows managers to monitor each stage of production and make sure everything is on schedule. If there is a delay at any point, they can quickly identify the problem and address it.

Managing Tools and Parts

In a busy manufacturing environment, tools and parts can easily get misplaced. RTLS helps track these items so workers always know where they are. This saves time and helps keep the production process moving smoothly.

Improving Workflow

By analyzing the data from RTLS, manufacturers can find ways to improve workflows and make processes more efficient. For example, if certain parts are consistently in the wrong place, they can make changes to ensure everything is where it needs to be when it’s needed.